Technology

UT tomography on complex shape components

1. Adaptive real-time 2D and 3D imaging on complex shape parts

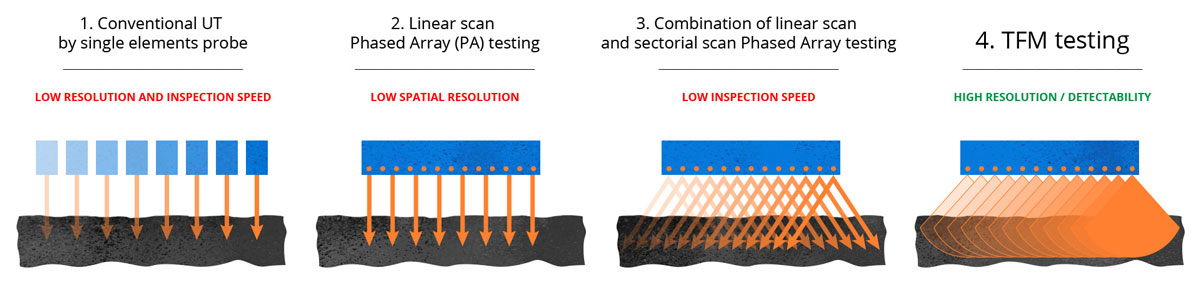

In early 2000 the conventional single channel pulse-echo testing of complex shape components e.g. made of CFRP, by single crystal ultrasonic transducers has been replaced by Phased Array testing, whereby time-consuming mechanical scanning of large square parts could be significantly speeded-up by fast electronic scanning with virtual transducer moving over the large aperture of a transducer array.

At the same time the spatial resolution and correspondingly the flaw detectability of this testing was remaining the same as by conventional single element probes since only normal beam insonification has been implemented by phased array transducers.

The ability of PA technique to sweep the angle of incidence for increasing the information content was not utilized due to significant slowing down of the inspection procedure.

In last decade the Total Focusing Method method (TFM) has been introduced that by means of specific reconstruction algorithms implements in one single pulsing-receiving procedure obtaining valuable information from many angles of incidence (Fig 1). It allows high speed testing with improved flaw detectability.

2. Adaptive real-time 2D and 3D imaging on complex shape parts

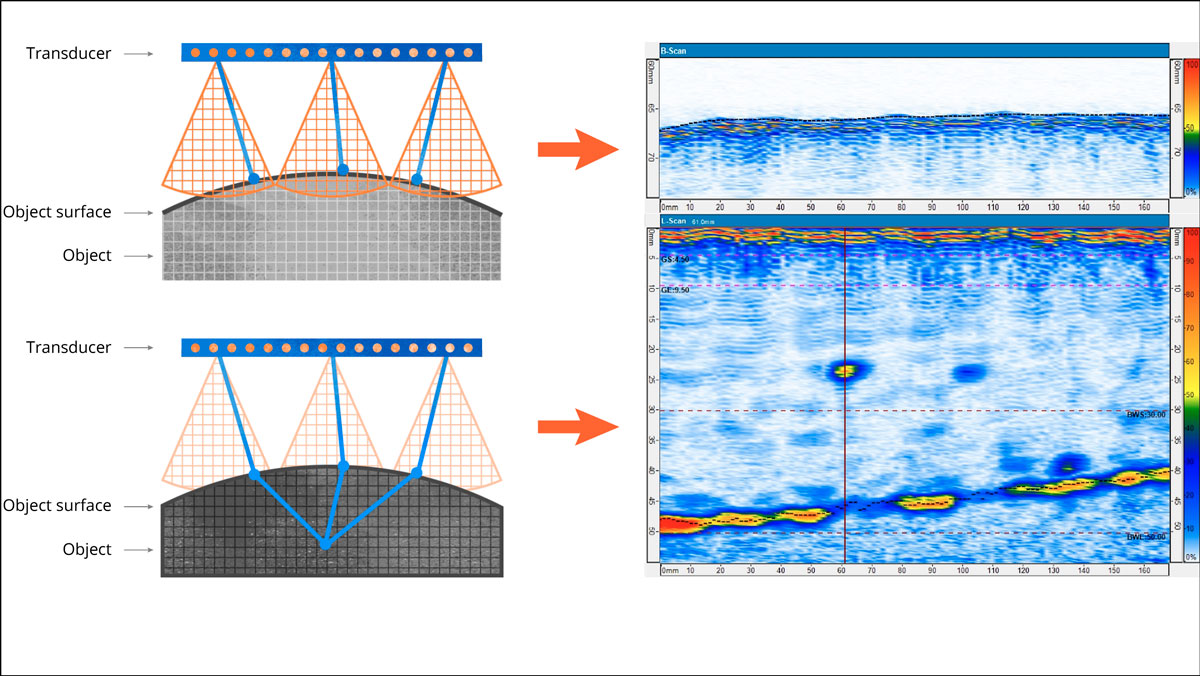

The further development of this approach consists in adaptive reconstruction routine especially for complex shape components that allows in first step of the data processing to recover the surface profile of the component to be inspected by performing Synthetic Aperture Technique (SAFT) reconstruction using sound velocity of the couplant and in the second step to perform volumetric reconstruction of the inspection object taking into account refraction on the curved surface:

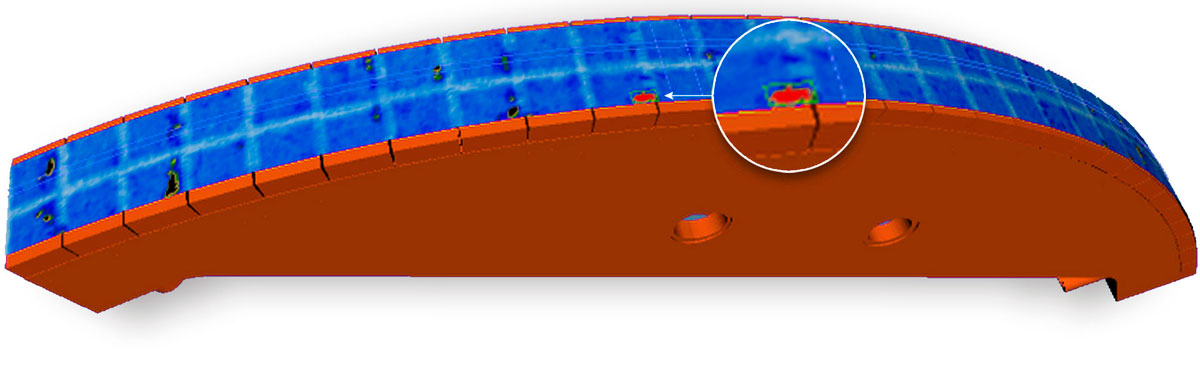

In combination with the robot-based inspection routines providing optimal orientation of the ultrasonic transducer to the inspection object with complex shape this approach will allow 2D and 3D imaging of those inspection parts with non-planar / non-plane-parallel geometry:

Contact us!

I-Deal Technologies provides leading edge automated systems and services for industrial ultrasonic imaging