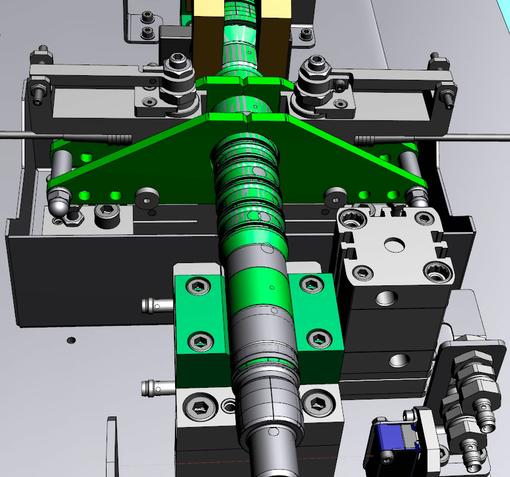

DHD Gauge

UT machine for measuring deep hole drillings (DHD) in ZF input shafts

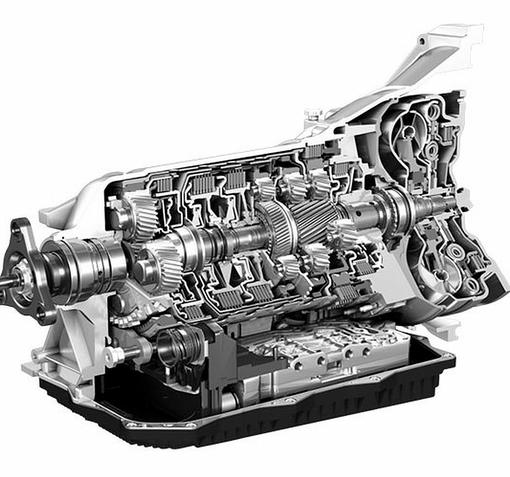

The ZF 8HP transmission since its introduction has been one of the top choices for international car manufacturers. Input shafts are the most crucial components of automatic gear boxes. High quality standard during the production requires specific inspection solutions also for internal design elements like deep hole drillings. The automatic ultrasonic inspection machine for inline measuring the deep hole drilling position of the 8HP input shafts is a key element of its quality assurance concept.

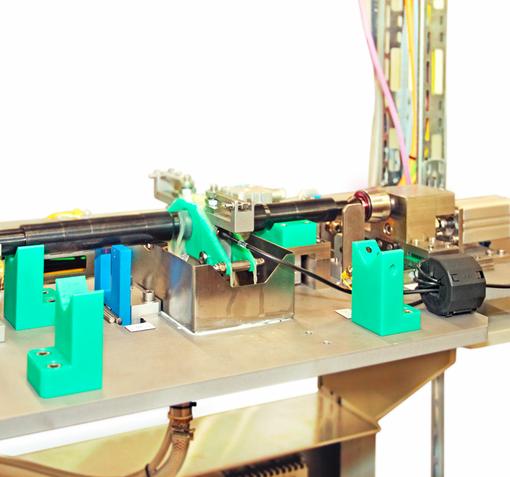

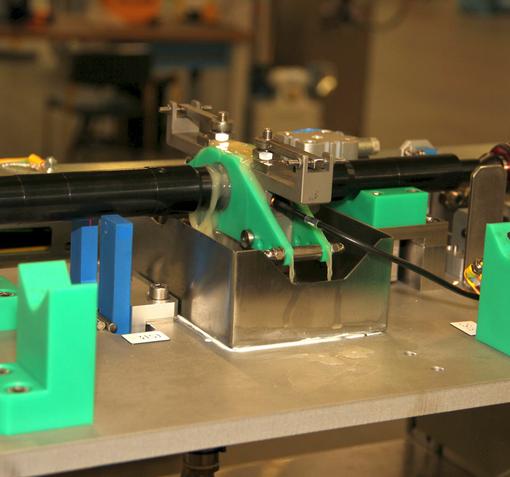

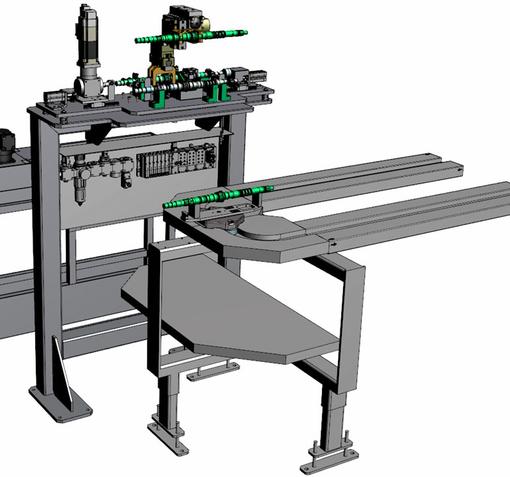

The ultrasonic inspection machine for automatic measuring the deep hole drilling position directly in production process is a special inspection solution implementing a high-end ultrasonic signal processing in combination with the robust and precise mechanical solution integrated in production line. The implemented local immersion coupling of ultrasonic waves allows wearless inspection procedure, whereby ultrasonic transducers have no mechanical contact with the shafts. The fully automatic work-flow including regular self-test of the machine by means of integrated control masters enable “uncrewed” 24/7 operation with interruption for seldom and short maintenance only. High precision and performance of the machine allow replacement of three operators a day previously engaged with the manual testing operation.

The system specification includes following functionality and modules:

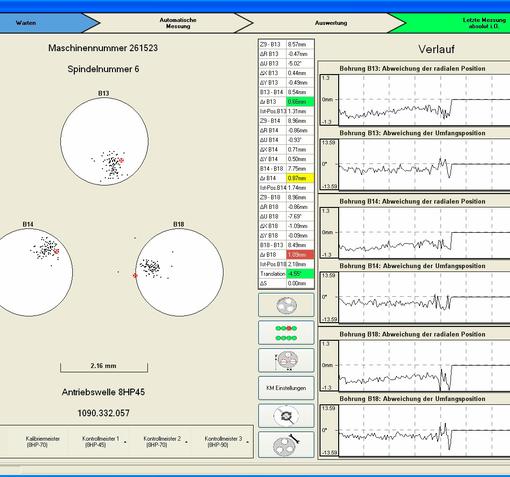

| Measurement cycle for one input shaft: | 20 sec. |

| Measurement accuracy: | +- 0.1 mm |

| Supported 8HP shaft types: | all |

| Loading / unloading the machine: | picker arm / gripper of the production line |

| Coupling medium: | drilling immulsion |

| Reporting: | DFQ data format according to customer specification |

Fully automated inspection process integrated in production including:

- Loading / unloading of the input shafts

- Self-control operation based on inspected part number and time intervals

- Adaptation of the inspection mechanics to the type of input shaft to be inspected

- Evaluation of 26 geometrical parameters of deep drillings in real time including feedback to the production control

- Statistical evaluation of the inspection results related to the drilling process

Contact us!

I-Deal Technologies provides leading edge automated systems and services for industrial ultrasonic imaging